Sheet Products

Choosing the right plate for the job is not easy…that’s why we created our Sheet Plate Selection Guide! We offer photopolymer plates for every application. Use this document to choose your plate and contact your Account Manager or local distributor for more information.

Digital Sheet

Digital sheet plates are designed to increase productivity in the platemaking process. MacDermid Graphics Solutions offers a comprehensive portfolio of round top and flat-top digital plates. Our sheet plate innovations, including our patented Clean Plate Technology, offer a wide range of solutions for today’s package printing challenges.

MacDermid offers a complete line of digital photopolymer plates for a simplified workflow. This entire line can be used with our award-winning LUX® Lamination system to deliver flat-top dots for the ultimate in print consistency and performance.

Analog Sheet

Our analog or conventional photopolymer sheet products are available for virtually any flexographic printing application and platemaking technology. From flexible packaging to corrugated boxes, MacDermid provides a high-quality photopolymer sheet plate product to fit your needs.

Analog Plates

- MAX

- MVP

- MGC

Equipment

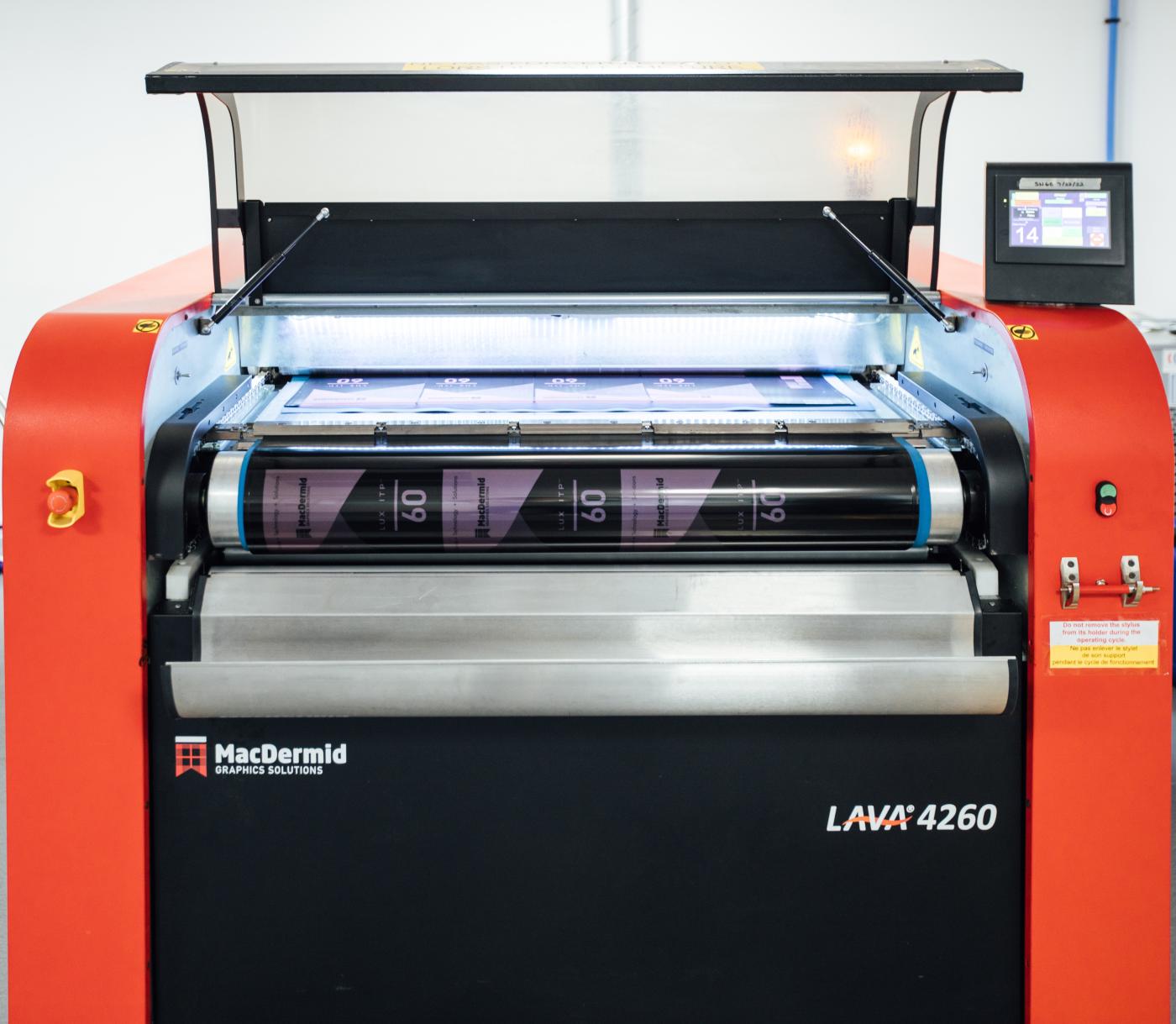

MacDermid Graphics Solutions offers a line of photopolymer sheet platemaking equipment. From lamination to thermal plate processing, MacDermid provides equipment to improve your platemaking workflow.

- Sheet Photopolymer Platemaking Equipment

- Solvent Platemaking Systems

- LAVA Thermal Processor